|

for S/N 481 thru 488

First version of the 1W-20 (S/N 1-200) Latest version of the 1W-20 (S/N greater than 500) Join the 1Watters QRPp email list See who is QRV on the QRV webpage Last Updated Tue, 13 Jul 2021 17:11:51 -0400 Always check the Addendum Section for updates |  |

Build this 20 Meter QRPp Transceiver for $46

Designed for 1 Watt output on 20 Meters using 12 VDC

VCXO Frequency Range is approximately 14,057 to 14,061 kHz

Full QSK, Dual Conversion Design

Includes built in keyer IC Version 4 with "natural" sidetone

The purpose of this transceiver is to provide a high quality

inexpensive transceiver for achieving DXCC and WAS via QRPp

This transceiver was designed for home and portable operation.

The name of this radio is "The One Watter" or "1Watter".

The Xcvr has low noise and is very sensitive and selective.

Minimum Discernible Signal or MDS is -137dBm (Independently Verified)

The VXO covers both sides of the standard 20 meter QRP calling frequency.

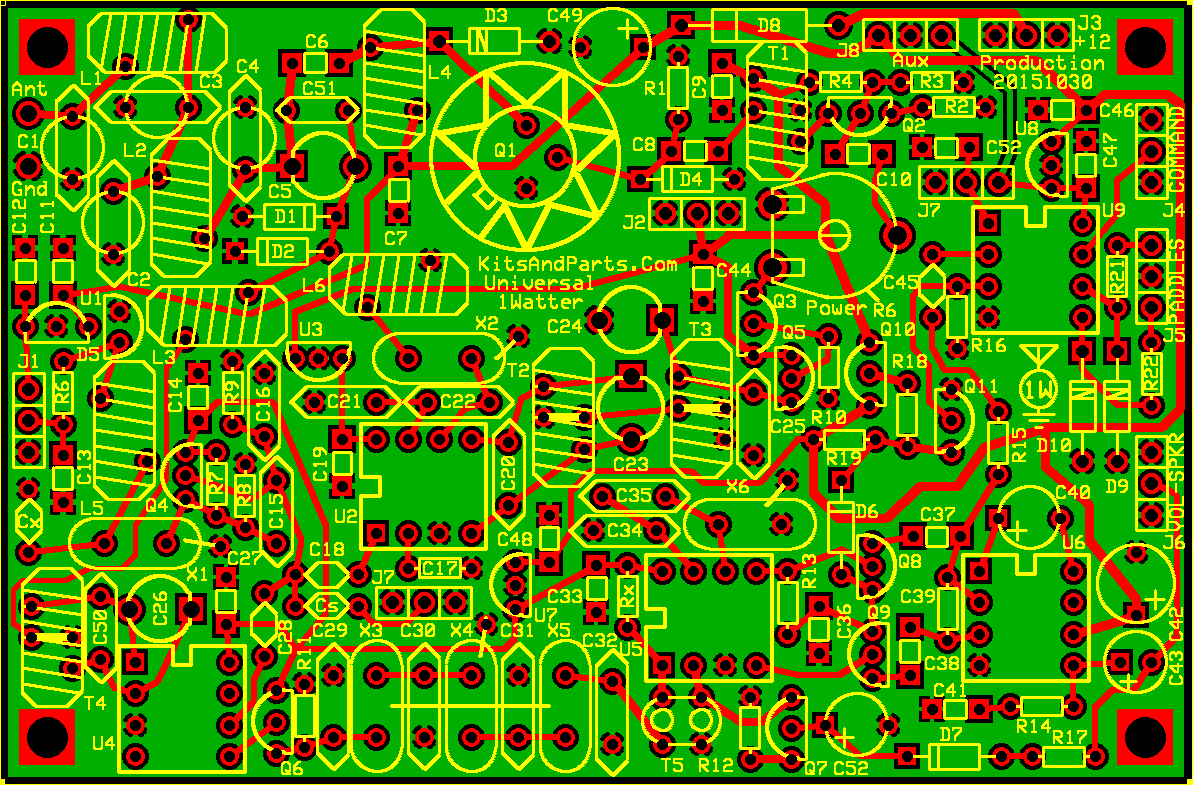

The PCB size is only 2.5" (63,5 mm) by 3.8" (96,5 mm)

I would like to thank Chuck Adams, K7QO for suggesting the new kit

and appreciate his help testing it to remove all the bugs and bad smoke.

He has some great pictures on his website at http://www.k7qo.net/onewatter.html

and a 10 part youtube video series 1Watter Transceiver Build, Phase 1 by K7QO

My personal operating experiences including QRPp WAS, QRPp DXCC and

Pictures, Data and Links are at http://1watters.com

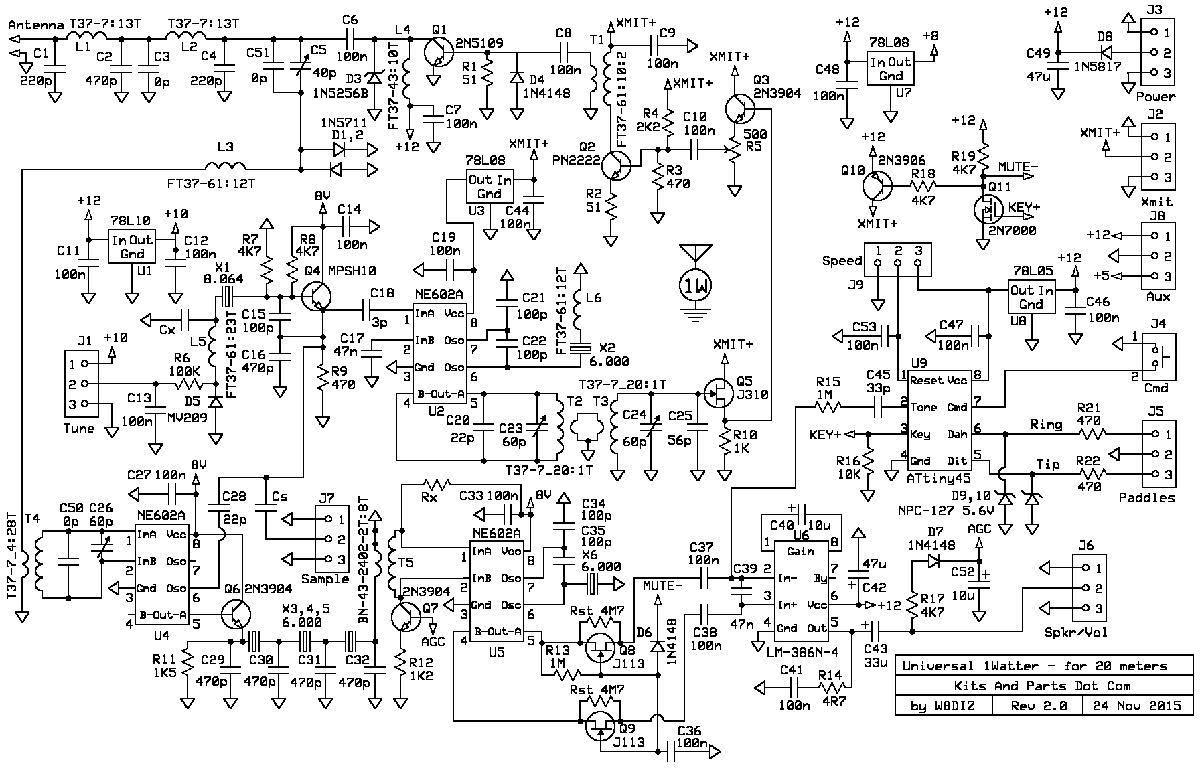

Full Size Schematic

Building Instructions:

DO NOT REMOVE ANY PARTS FROM THE PLASTIC BAGS UNTIL INSTRUCTED TO DO SO

1. Be careful if you inventory the parts; they are small and easy to lose. Parts List

Do not mix up the toroids between the plastic bags.

Keep all toroids in their plastic bags until called for installation.

Do not mix up the blue 1N5711 signal diodes with the blue NPC-127 zener diodes.

The 1N5711 signal diodes are taped together and the zeners are loose.

If you are missing any parts, contact me immediately. I will ship the parts the same day.

If you find extra parts in the kit, check the Addendum else throw them in your junk box.

This kit includes all parts to create a functioning transceiver EXCEPT the tune pot.

Included parts are: 2 phone jacks, a bnc jack, a push-button, volume control pot, magnet wire and heat sink.

This kit uses several all black ferrite toroids. One (1) FT37-43 and multiple FT37-61 toroids; they look the same.

The FT37-43 is included in the bag with the SMT capacitors.

Mark the bag with the SMT caps as "-43" and the bag with the resistors as "-61"

This will help with identification later on when installing inductors and transformers.

Install the parts in the order per this document to prevent mechanical installation problems later.

Each 1Watter is provided with a Serial Number, which is attached to the bag holding the PCB and magnet wire

Attach the label to the rear of your 1Watter enclosure or wherever suitable

The Serial Number may later be used for tracking 1Watter QSO contests.

This kit requires the following items to complete the kit:

hook-up wire/coax to connect the PCB to the chasis and an optional power on/off switch and optional case.

Any Addendums will be listed by date at the end of this document

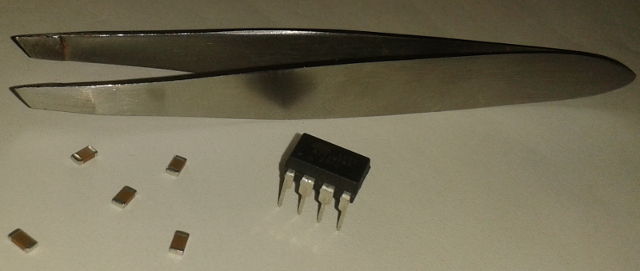

2. Install all SMT capacitors

These capacitors are easy to install, especially if you have some kind of part holding/positioning tool.

I find a plain wooden toothpick will hold the 1206 size caps while soldering but

my favorite tool is a pair of diagonal headed tweezers

There are 21 pieces 100n SMT capacitors on the PCB

C53 is labeled as C52 on the PCB, below R2

____C6,7,8,9,10,11,12,13,14,19,27,33,36,37,38,41,44,46,47,48,53

3. Install all 1/8 Watt Resistors.

You will need a magnifying device to verify the resistor color codes.

Bend the resistor leads a sharp 90 degrees from the body of the resistors.

R20, the volume control will be connected later.

Save 5 cut resistor leads to ground the crystal cases later.

____R1,2: 51 Green-Brown-Black-Gold

In the next step, see Addendum ref R23

____R3,9,21,22,23: 470 Yellow-Violet-Brown-Gold

____R4: 2K2 Red-Red-Red-Gold

____R5: 500 Horizontal mounted pot (in hardware bag)

____R6: 100K Brown-Black-Yellow-Gold

____R7,8,17,18,19: 4K7 Yellow-Violet-Red-Gold

____R10: 1K Brown-Black-Red-Gold

____R11: 1K5 Brown-Green-Red-Gold

____R12: 1K2 Brown-Red-Red-Gold

____R13,15: 1M Brown-Black-Green-Gold

____R14: 4R7 Yellow-Violet-Gold-Gold

____R16: 10K Brown-Black-Orange-Gold

There are two 4M7 resistors; see Addendum ref Natural Sidetone Mod

4. Install all Diodes - observe polarity.

____D1,2: 1N5711 blue glass diodes

____D3: 1N5256B silver 30 V Zener

____D4,6,7: 1N4148 red glass diodes

____D5: MV209 varactor - leave 1/8 inch (3 mm) space between the PCB and diode body

____D8: 1N5817 black diode

____D9,10: NPC-127 blue 5.6 V Zener

5. Install all IC sockets - observe polarity.

____U2,4,5,6,9: Match the notch on the IC socket with the pattern on the PCB

6. Install all remaining capacitors in the order shown.

____C5: 40p yellow trimmer cap - flat side into square hole

____C23,24,26: 60p brown trimmer caps - flat side into square hole

____C1,4: 220p labeled 221J NPO disc cap

____C2: 470p labeled 471J SL disc cap

____C3: empty

____C15,21,22,34,35: 100p labeled 101J NPO disc or 101 yellow mono

____C16,29,30,31,32: 470p labeled 471J small yellow caps

____C17,39: 47n labeled 473 small yellow axial cap

____C18: 3p0 labeled 3 dark tan disc cap

____C20,28: 22p labeled 22J NPO disc

____C25: 56p labeled 56J orange disc

____C40,52: 10uF black electrolytic - observe polarity

____C42,49: 47uF blue electrolytic - observe polarity

____C43: 33uF black electrolytic - observe polarity

____C45: 33p labeled 33J NPO dark tan disk cap

____C50: empty

____C51: empty

____Cs: empty - see Mods section

____Cx: empty - see Mods section

7. Install all Voltage Regulators and Transistors

Do not install Q1 at this time.

____U1: 78L10 voltage regulator; note orientation on the PCB

____U3,7: 78L08 voltage regulator; note orientation on the PCB

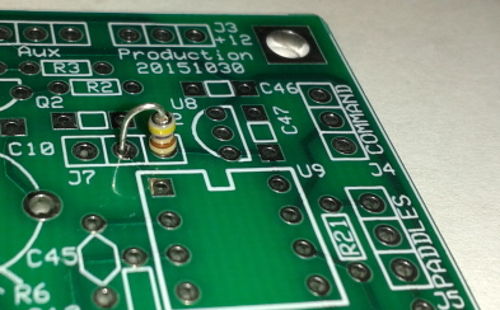

____U8: 78L05 voltage regulator; note orientation on the PCB

Temporarily connect a +12V source in series with a 100-200 ohm current

limiting resistor to J3-2 pad and power supply ground to J3-3 pad (ground)

Measure the output voltages of U1 (10V), U7 (8V) and U8 (5V) to make sure they are correct.

Temporarily put a clipped resistor lead from emitter to collector of transistor Q10

Measure the output voltage of U3 (8V) to make sure it is are correct.

Remove the clipped resistor lead and remove the power source and continue with parts installation.

____Q2: PN2222

____Q3,6,7: 2N3904

____Q4: MPSH10

____Q5: J310

____Q8,9: J113

____Q10: 2N3906

____Q11: 2N7000 - CAUTION...static sensitive

8. Install all five 8-pin DIP ICs.

____U2: NE602A balanced mixer; the dot positioned towards C18

____U4: NE602A balanced mixer; the dot positioned towards C26

____U5: NE602A balanced mixer; the dot positioned towards C32

____U6: LM386N-4 audio amplifier; the dot positioned towards C37

____U9: ATtiny45 Keyer with Sidetone; the dot positioned towards C52

9. Wind and install all Toroid Inductors. Wind all wires on the toroids clockwise.

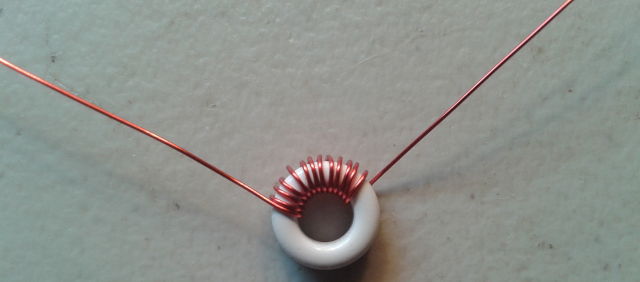

9.1 Install inductors L1 & L2

Cut two 11" pieces of #26 red wire.

____L1,2: Wind 13 turns of #26 red wire on the T37-7 white toroid, tightly spaced.

Trim the wires of L1 and L2 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Spread the turns over most of the toroid

Install L1 & L2 into the PCB, pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.2 Install transformer T4

Cut 18" of #30 red wire and 6 inches of #27 green wire.

____T4: Wind 28 turns of #30 red wire on an T37-7 white toroid, tightly spaced.

Trim the #30 wires of T4 to one inch.

Wind 4 turns of #27 green wire on the T37-7 white toroid, tightly spaced.

Trim the #27 wires of T4 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Install T4 with the #30 wires into the outside (upper and lower) holes on the PCB

and the 4 turn #27 wire thru the center holes of the PCB for T4

pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.3 Install transformer T2

Cut 14" of #30 red wire and 4 inches of #27 green wire.

____T2: Wind 20 turns of #30 red wire on an T37-7 white toroid, tightly spaced.

Trim the #30 wires of T2 to one inch.

Spread the turns over most of the toroid

Wind 1 turn of #27 green wire on the T37-7 white toroid.

Trim the #27 wires of T2 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Install T2 with the #30 wires into the outside (upper and lower) holes on the PCB

and the single turn #27 wire thru the center holes of the PCB for T2

pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.4 Install transformer T3

Cut 14" of #30 red wire and 4 inches of #27 green wire.

____T3: Wind 20 turns of #30 red wire on an T37-7 white toroid, tightly spaced.

Trim the #30 wires of T3 to one inch.

Spread the turns over most of the toroid

Wind 1 turn of #27 green wire on the T37-7 white toroid.

Trim the #27 wires of T3 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Install T3 with the #30 wires into the outside (upper and lower) holes on the PCB

and the dual turn #27 wire thru the center holes of the PCB for T3

pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.5 Install inductor L4

Cut 9" of #27 green wire.

____L4: Wind 10 turns of #27 green wire on an FT37-43 black ferrite toroid, tightly spaced.

The FT37-43 black ferrite toroid is packed in the bag with the SMT caps

Trim the wires of L4 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Spread the turns over most of the toroid

Install L4 into the PCB, pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

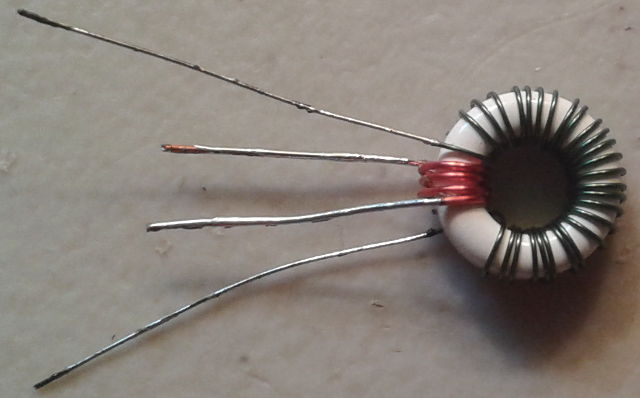

9.6 Install transformer T1

Cut 9" of #26 red wire and 4 inches of #27 green wire.

____T1: Wind 10 turns of #26 red wire on an FT37-61 black ferrite toroid, tightly spaced.

The FT37-61 black ferrite toroids are packed in the bag with the resistors

Trim the #26 red wires of T1 to one inch.

Wind 2 turns of #27 green wire on the FT37-61 black toroid, tightly spaced.

Trim the #27 green wires of T1 to a half inch.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Install T1 with the #26 wires into the outside (upper and lower) holes on the PCB

and the dual turn #27 wire thru the center holes of the PCB for T1

Pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.7 Install inductor L3

Cut 10" of #26 red wire.

____L3: Wind 12 turns of #26 red wire on an FT37-61 black ferrite toroid, tightly spaced.

The FT37-61 black ferrite toroids are packed in the bag with the resistors

Trim the wires of L3 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Spread the turns over most of the toroid

Install L3 into the PCB, pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.8 Install inductor L6

Cut 10" of #26 red wire.

____L6: Wind 12 turns of #26 red wire on an FT37-61 black ferrite toroid, tightly spaced.

The FT37-61 black ferrite toroids are packed in the bag with the resistors

Trim the wires of L6 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Spread the turns over most of the toroid

Install L6 into the PCB, pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.9 Install inductor L5. This inductor determines the upper and lower frequencies of the 1Watter.

Cut 16" of #30 red wire.

____L5: Wind 23 turns of #30 red wire on an FT37-61 black ferrite toroid, tightly spaced.

Trim the wires of L5 to a half inch each.

Tin & Strip the insulation to the base of the toroid using a hot solder pencil.

Spread the turns over most of the toroid

Install L5 into the PCB, pull the leads tight using needle nose pliers, solder and trim

You should be able to straighten the toroid to match the outline on the PCB

9.10 Install transformer T5

Cut 10" of #34 red wire and 4" of #30 red wire.

____T5: Wind 8 turns of #34 red wire on an BN-43-2402 black ferrite binocular.

The BN-43-2402 black ferrite binocular is packed in the bag with the SMT caps

Trim the red wires of T5 to one inch each.

Wind 2 turns of #30 red wire on the BN-43-2402 black ferrite binocular.

Trim the #30 wires of T5 to one half inch each.

Tin & Strip the insulation on all 4 wires to the base of the binocular.

The #34 wire leads for the 8 Turn winding go to the two pads closest to the IC, Pins 1 and 2.

The #30 wire leads go to the two pads farthest away from the IC or toward the bottom of the PCB.

Install T5 into the PCB, pull the leads tight using needle nose pliers, solder and trim.

10. Install all Crystals.

There are 5 pieces of 6.000 mHz crystals included in the kit.

These crystals are graded for frequency and resistance.

If you find a crystal with a black dot, install it in X6.

If you find 2 crystals with black dots, install in X2 & X6.

The Filter Crystals X3,4,5 should not have a black dot.

When installing the crystals, tilt the crystals about 20 degrees while soldering

This will raise the crystal a small bit above the PCB after straightening

and will prevent trace shorts to the case of the crystal

Do not overheat the crystals.

____X1: 8.064 mHz crystal

____X2,3,4,5,6: 6.000 mHz crystals

When soldering the crystal cases to ground, do not overheat the crystals

____Solder one resistor lead across the top of crystals X3,4,5

____Solder one resistor lead from the top of X4 to the ground below (top center)

____Solder one resistor lead from the top of X2 to the ground below (upper right)

____Solder one resistor lead from the top of X6 to the ground below (upper right)

11. Connections.

Recommend chassis/enclosure for the 1Watter from mouser.com Part # 537-CR-442

Connect a user supplied pot (5K or 10K or 100K) to the "speed pot" connector J9.

Connect the speed pot control wiper to the center hole on J9.

If you do not install a speed pot then see the Addendum to install R23.

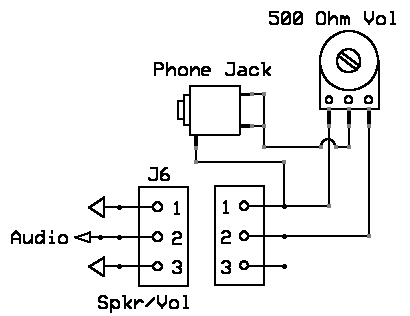

Connect the 500 ohm volume pot (R20) using any insulated wire.

Connect the volume control high side to the center of J6 on the PCB.

Connect the volume control cold side to a ground on J6.

Connect the volume control center wiper to a 3.5 mm phono jack

Connect the 3.5 mm phono jack ground to the cold side of the volume control pot.

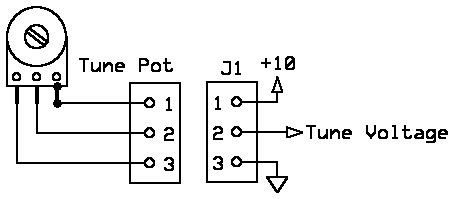

Connect a user supplied pot (5K or 10K or 100K or 1 Meg) to the "Tune" connector J1.

Connect the tune control wiper to the center hole on J1.

Connect the provided BNC connector to the "Ant" connection next to L1 on the PCB.

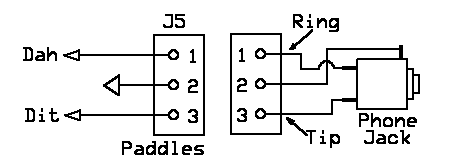

Connect paddles or a straight key to J5 via the other 3.5 mm phono connector

Connect the Push Button, one wire to the center of J4, the other wire to one of the ground connections

Before you apply power to the 1Watter, make sure your power polarity is correct

The 1Watter was designed to operate from a 12 volt Sealed Lead Acid Battery

Connect +12.6V volts (+/- 1 volt) to the holes in the upper right corner of the PCB.

12. Receiver Alignment.

Connect any antenna to the 1Watter. Anything from a 2 foot wire up a large antenna.

Apply power to the 1Watter and set the volume control to maximum.

Adjust C5 and C26, back and forth for maximum noise coming from the speaker/headphones.

If you connected an antenna, you may hear CW signals by tuning the Tune Pot.

13. Transmit Alignment using an Oscilloscope or a Calibrated Accurate Receiver

The band pass filter (X3,4,5) center frequency is 5,998.6 kHz +/- 100 Hz

The transmit oscillator part of U2, X2 and L6 should match that frequency +/- 100 Hz.

Find a signal in the tune range of the transceiver. As you tune across the signal,

the loudest audio frequencies should be about 600 Hz +/- 100 Hz

Next we will adjust for maximum carrier output. You will need a 20 meter receiver or an oscilloscope.

If you do not have either, we will align the transmitter after we install the final transistor.

The Tune Control Oscillator operates from 8,058.4 to 8,062.4 kHz

The Transmit Carrier Oscillator operates at 5.998.6 kHz

These two signals are mixed to produce the 14,060 +- kHz transceiver frequency, but

the mixer also produces other frequencies that must be rejected.

Preset the power control R5 to half way

Preset C23 for 30 percent maximum capacitance

Preset C24 for 50 percent maximum capacitance (see settings in addendum section)

C23 has broad tuning while C24 has very sharp tuning.

Preset the tune control to mid position

Place the Keyer into straight key mode

While listening to a receiver near 14,060 kHz or watching a scope at the junction of R1/D4,

key the transmitter and adjust C24 to max signal on the scope or receiver.

If using a receiver, you will need to hunt for the actual signal.

After finding the signal, readjust both C23 and C24 for maximum signal.

After alignment, C23 should be near 30 percent maximum capacitance

and C24 should be near 50 percent capacitance.

Make sure that you have aligned the filter to the correct frequency and not an alternate

frequency generated by the transmit mixer. Measure the frequency using a scope of freq counter.

14. Install the RF Final Transistor Q1

____Q1: 2N5109 - leave 1/8 inch (3 mm) space between the PCB and transistor case

____Q1 heat sink: - push the heat sink over the case of Q1; align heat sink to match PCB pattern.

15. Sidetone volume setting.

The cmd sidetone volume is fixed/set by R15, 1M & C45, 33p.

To lower the cmd sidetone volume, decrease the value of C45 or increase the value of R15

To raise the cmd sidetone volume, increase the value of C45 or decrease the value of R15

The natural sidetone volume is sent by the two (2) 4M7 Rst resistors on Q8 & Q9

16. Transmit Final Alignment using milliamp meter

Connect a 50 ohm dummy load to the output of the transceiver and power up with 12V.

Place the keyer into straight key mode (see instructions below)

Connect xcvr to power supply through an amp meter, 250 mA or greater.

Key the transmitter and adjust R5 for exactly 250 milliamps.

If C23 & C24 were not aligned in a prior step then preset C23 to 30 pct and C24 to 50 pct capacitance

Ajusting C24 for maximum milliamps current. Adjust R5 to keep the current at 250 Ma.

repeat several times until you know that C23 & C24 are peaked and R5 is set for 250 Ma.

After alignment, C23 should be very near 30 percent capacitance

and C24 should be very near 50 percent capacitance.

If you have a wattmeter, insert it between the dummy load and the tranceiver.

It should measure very near 1 watt output.

You may also adjust R5 for 20 volts P-P on a scope.

It is recommended that you do not adjust R5 for more than 1 watt to prevent instability.

This completes the 1Watter Tranceiver alignment.

The 1Watter Service Manual

17. Optional modifications to and experiments with the 1Watter

17.1 NE602A gain increase for U4 and U5

You may increase the gain by placing a 27K (not included) or higher value resistor (Rx on the PCB) across pins 1 and 8 of U5

17.2 Frequency Range Mods

You may change the frequency span of the 1Watter by changing the number of turns on L5

Too many turns and the oscillator stops working or becomes unstable.

Add capacitance at Cx, between the crystal X1 and L5 and ground. Try 3-10 pF for starters.

18. The 1Watter Keyer Instructions

This is a very basic Iambic-Mode-B Keyer using an ATmel AVR Microprocessor

On power-Up, the keyer defaults to 15 WPM and a sidetone of 625 Hz and annunciates "1W" [ .---- .-- ] via Int'L Morse Code.

Connecting a straight key with a Mono Plug automatically places the keyer into straight key mode.

Moving the "Speed Pot" changes the speed from 5 WPM up to 36 WPM (version 3 and higher only)

The internal timing oscillator in the Keyer Chip is an RC oscillator that runs at 9.6 MHz +/- 10 pct Factory Calibration.

Typical accuracy is +/- 5 percent; The accuracy can be impoved to +/- 2 percent if one takes the time to calibrate

the oscillator and reprogram the keyer chip. This procedure is too time consuming for 200 chips but may be OK for you.

The accuracy is typically +/- 5 pct so your sidetone may be off by +/- 5 pct and your keying WPM may also be off.

That means if you set the WPM speed to 20 WPM, you may actually have it set at 19 or 21 WPM; should not be a problem.

The keyer is placed into the "Command" mode by pressing and releasing the Cmd Button.

The keyer has the following commands available after pressing the Cmd Button:

"A" (.-) Toggles transmit sidetone audio

The sidetone mode setting is saved on power-down.

If transmit sidetone flag was set, then clear flag and announce "Y"; Y=yes, we turn on transmit sidetone audio

If transmit sidetone flag was clear, then set flag and announce "N"; N=no, we turn off transmit sidetone audio

CMD Sidetone Audio is always active when a CMD is issued.

Enable this Mode when using the "natural" transmit sidetone.

"B" (-...) Enter Beacon Mode (version 2 and higher only)

Hit CMD button and enter "B" to start Beacon Mode

Listen for a DIT to acknowledge ready to select message number

Enter message number...1, 2 or 3

Message repeats over and over

Hit paddles, dit or dah or straight key to turn off beacon mode

"E" (.) or "T" (-) Toggles between normal keyer and straight key mode, acknowleged by annunciating

"S" (for Straight Key Mode) in code. The keyer mode is NOT saved on power-down.

Connecting a straight key with a Mono Plug automatically places the keyer into straight key mode.

"M" (--) Enter Beacon Message(s) (version 2 and higher only)

Hit CMD button and enter "M" to enter message

Listen for a DIT to acknowledge ready to select message number

Enter message number...1, 2 or 3

Listen for a DIT to acknowledge ready to enter a character

Enter one character at a time, then wait for another "dit"

To enter a word space, do not enter anything in between annunciated "dits"

At the end of the message, do not forget to add empty character time.

This allows you to pause and listen between CQ calls. Recommend between 10 and 20 word spaces.

Terminate message entry mode by send "AR" or ".-.-."

"R" (.-.) Toggles between normal and reverse paddles keys, acknowleged by annunciating "P" (for normal paddles)

or "X" (for reversed paddles) in code. The paddles (normal or reverse) are saved on power-down.

"S" (...) Set keyer speed in WPM. Speed is entered as two numerical digits.

After sending the "S" command, the keyer sends a DIT (e) as a prompt for the first speed character (0-4)

After sending the first speed number, wait for another DIT (e) prompt and send the 2nd number (0-9)

Depending upon what you enter, you will hear a "?" for ERROR or an "R" for a "Roger" acknowlegement.

Valid keyer speeds are 1 to 45 WPM (good luck trying to send/use 1 WPM)

The keyer speed setting is saved on power-down.

"F" (..-.) Sets the sidetone frequency.

After sending the "F" command, the keyer sends a DIT (e) as a prompt for the tone character (0-9)

Depending upon what you enter, you will hear a "?" for ERROR or an "R" for a "Roger" acknowlegement.

The sidetone frequency setting is saved on power-down.

The following table equates the sidetone number with the sidetone frequency:

0 = 1000 Hz

1 = 833 Hz

2 = 714 Hz

3 = 625 Hz

4 = 555 Hz

5 = 500 Hz

6 = 455 Hz

7 = 417 Hz

8 = 385 Hz

9 = 357 hz

"V" (...-) Announces the keyer version number (version 0 and higher only)

This kit includes keyer version 4.

"X" (-..-) Puts the keyer into transmit or tune mode

Hit paddles dit or dah or straight key to turn off tune mode

The keyer has Deadman Insurance. In the event that the keyer issues 64 successive DITs or

64 successive DAHs, the keyer will shut down and cease to operate.

You must power down the keyer chip to restart normal operation.

To Reset the Keyer to the Default mode, hold the Cmd button active until you hear "1W"

Then immediately release the Command Button, else you will send another Command request.

Source code and hex files for the keyer are available at http://kitsandparts.com/keyer

Addendum Section:

Oct 31 2015 1247 - On the PCB, the power control pot labeled R6 should be labeled R5

Nov 16 2015 1259 - On the PCB, the speed pot connector J7 above to the keyer chip should be labeled J9

Nov 16 2015 1259 - On the PCB, C52 above the keyer chip should be labeled C53

Nov 16 2015 1259 - If you are not installing a keyer speed pot then you must install R23.

Install R23, 470 ohms, into the center and right two holes of J9.

This mod supplies 5 volts to the A/D Pin-1 on the keyer chip.

Nov 16 2015 1259 - The Natural Sidetone Mod is in the Addendum because the Mod did not make it onto the production PCB.

Perform this Mod after the 1Watter is built and tested.

Install a 4M7 ohm resistor on the bottom of the PCB across the Drain and Source of Q8

Install a 4M7 ohm resistor on the bottom of the PCB across the Drain and Source of Q9

Feb 16 2016 1435 - Relabeled C22 & C35 on schematic from 180pF to 100 pF

Variable capacitor settings:

| Maximum Capacitance | Midway Capacitance | Minimum Capacitance | |||

|---|---|---|---|---|---|

|  |  |

If you need an alignment tool for the trimmers, look up "GC 8608" - available at newark.com and onlinecomponents.com

End of Addendum Section: top